The “Tool Interference Problem” Is the Silent 5-Axis Killer

5-axis machining promises fewer setups and better accuracy—but only if you can actually reach the faces you need without colliding with the part, fixture, hydraulic vise body, or the table. In many real shops, the limiting factor isn’t CAM. It’s access.

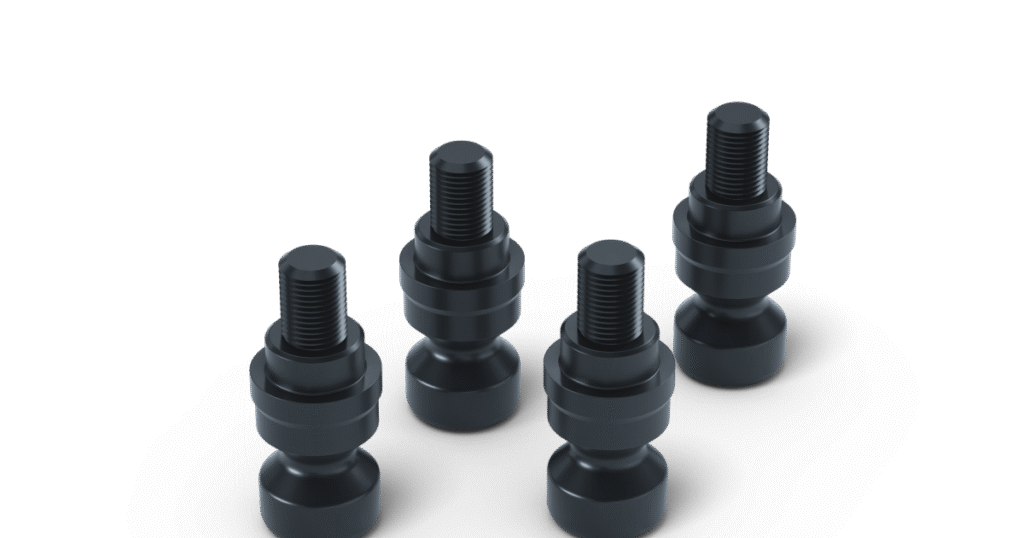

That’s why riser blocks (heightening blocks) and pyramid fixtures are becoming a hot topic in 5-axis workholding: they solve access and collision risk in a mechanical way, often with faster payoff than reworking programs.

Riser Blocks: Elevation Creates Clearance

A riser block’s job is simple: raise your workholding above the turntable surface so the spindle and toolholder can approach from more angles.

A concrete example is described as the D325-L100 heightening block, which “raises the vise 100mm from the turntable surface for better access to all five sides of the workpiece in 5-axis applications,” specifically reducing tool holder and tool interference issues. That one sentence captures why risers matter:

- better access,

- fewer collisions,

- more usable tool angles.

Why 100 mm Height Can Be a Big Deal

Even a modest height increase can turn an impossible toolpath into a safe one. Without elevation, your toolholder often clips the vise body before the cutter reaches the feature—forcing you into longer tools, weaker tooling, chatter, and compromised surface finish.

Risers let you use:

- shorter tools (stiffer),

- more direct tool angles,

- safer retracts and approach moves.

Stack Strategy: Riser + Zero-Point + Vise

The same riser description references combining a zero-point positioning chuck and a 5th axis vise to quickly position and clamp workpieces. This is the modern “stack” approach: each layer solves one problem.

- Zero-point: fast, repeatable setup

- Vise: stable clamping and jaw options

- Riser: access and clearance

When these layers are designed to work together, changeovers become faster and 5-axis becomes less stressful.

Pyramid Fixtures: Angles Reduce Interference by Design

A pyramid fixture takes a different approach: instead of lifting everything, it orients the workpiece surfaces at angles so tools can reach features without running into the fixture body.

A pyramid-style product description explicitly notes:

“The pyramid fixture has 20° angles on all four sides, which is beneficial for reducing tool interference and improving machining efficiency.”

That’s exactly why pyramid fixtures are trending:

- the geometry bakes in clearance,

- you can often machine multiple faces without re-clamping,

- you can run multiple parts in a compact footprint.

When to Use a Riser vs a Pyramid

Use a riser when:

- you already have a reliable vise/fixture strategy

- you just need more clearance for toolholders

- you want to keep parts “flat” but raise the entire setup

(Example: raising a vise 100 mm to access five sides more easily.)

Use a pyramid when:

- you want multi-face access without tall stacks

- you want built-in clearance from angled faces

- you’re optimizing for cycle efficiency on multi-side work

(Example: 20° angled sides to reduce interference.)

In reality, many advanced setups use both: a riser for global clearance, plus angled/3D fixtures for local access.

A Practical Collision-Reduction Workflow

If you want to reduce collisions and improve stability quickly, follow this process:

- Identify where interference happens

- Is it the toolholder hitting the vise?

- Is it the spindle nose limiting tilt?

- Is it the part too close to the table plane?

- Try elevation first

A riser often fixes the biggest clearance problems with minimal workflow disruption. - Use angled fixtures for dense part families

If you’re trying to machine multiple parts per cycle or multiple faces per clamp, pyramids can create access without overly tall tooling stacks. - Standardize the stack

Once you find a stable setup, standardize it as a repeatable “package” so every operator runs it the same way.

Why This Matters Beyond Safety: It Improves Quality

Collision avoidance is obvious. But access improvements also drive:

- better surface finish (shorter tools, less chatter),

- more accurate features (less tool deflection),

- more consistent results across multiple runs.

Even the riser description highlights repeatable positioning consistency as important for high-precision machining (noting repeatable accuracy at the micron level in typical use). Xindian CNC

Whether or not every job truly needs micron-level repeatability, the principle stands: stability and access are quality multipliers.

Bottom Line: Access Is the Real Foundation of 5-Axis Efficiency

If your 5-axis machine is underperforming, don’t start by blaming CAM. Start by asking: Can the tool safely reach what it needs to reach with a stiff tool?

Riser blocks and pyramid fixtures are popular because they answer that question mechanically:

- raise the work,

- angle the work,

- reduce interference,

- increase usable toolpaths.

CTA: If you’re planning a 5-axis workholding upgrade, begin with one part family and solve access first. Once collisions disappear, everything else—cycle time, finish, tool life—gets easier.